Smart MES Software for Digital Manufacturing Transformation

Our MES System Capabilities

Manufacturing Execution Systems (MES) for Connected, Efficient Operations

Manufacturing Execution Systems (MES) for Connected, Efficient Operations

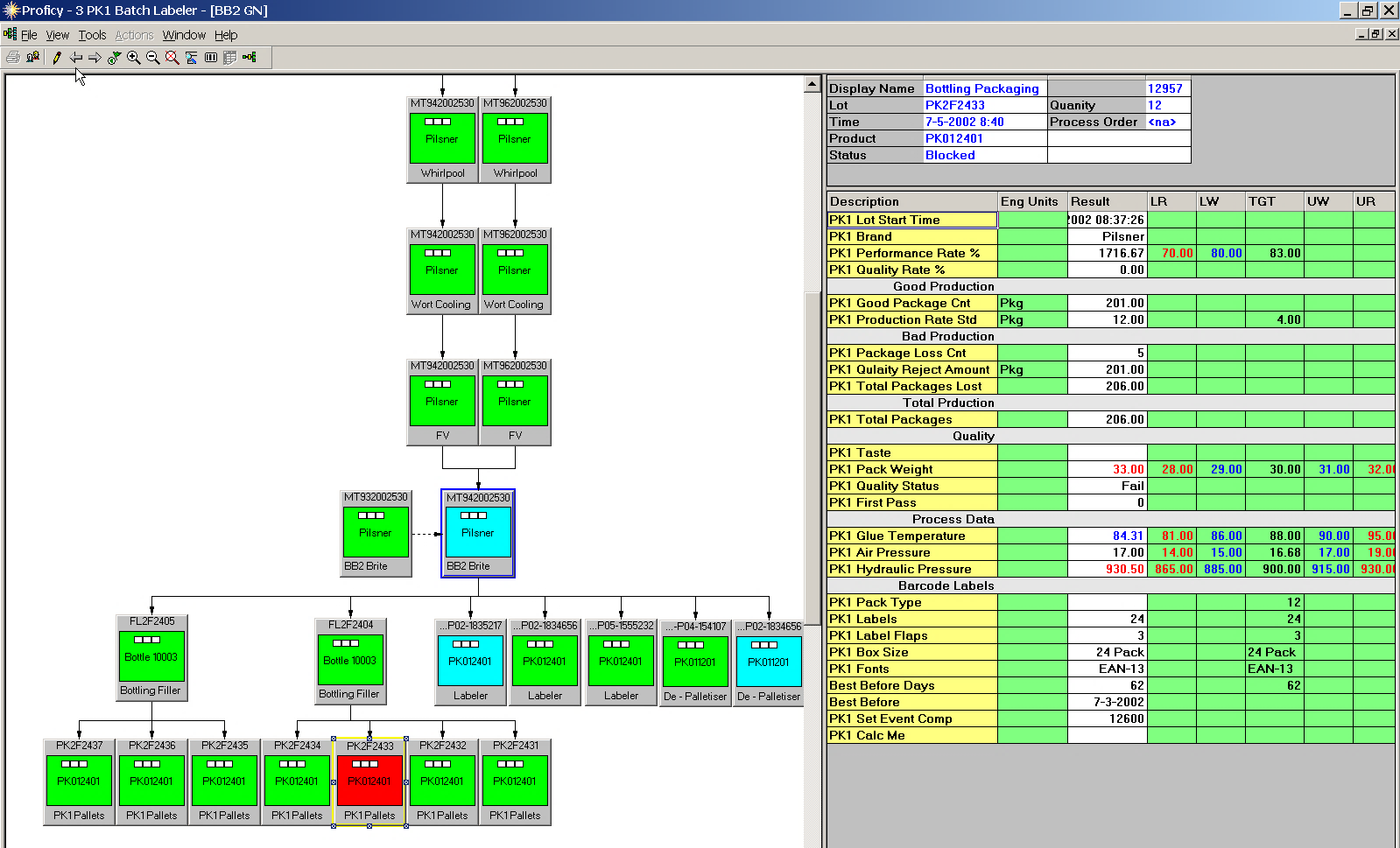

At Allied Solutions, our advanced Manufacturing Execution Systems (MES) enable real-time, data-driven control of production processes. Designed to support digital transformation for manufacturing, our MES software integrates Industrial Iot, machine learning, and predictive analytics to optimise every stage of your operations.

Whether you’re aiming to increase production efficiency, reduce waste, or improve quality and delivery performance, our MES system offers a flexible and scalable solution tailored to your unique manufacturing environment.

Key Features of Our MES Manufacturing Solutions

Inventory Management

Improve inventory accuracy and reduce working capital requirements. Our MES software enhances visibility across the supply chain, enabling leaner production and smarter material usage.

Production Control

Plan, schedule, and execute production with precision. Our MES system helps improve on-time delivery and manufacturing agility through real-time monitoring and adaptive scheduling tools.

Quality Management

Ensure consistent product quality with a closed-loop quality control system. Gain insights into root causes of defects and leverage data-driven improvements to maintain high standards.

Predictive Maintenance

Enhance asset reliability and minimise unplanned downtime. You can extend equipment life and maximise OEE through predictive maintenance powered by MES and IIoT integration (Overall Equipment Effectiveness).