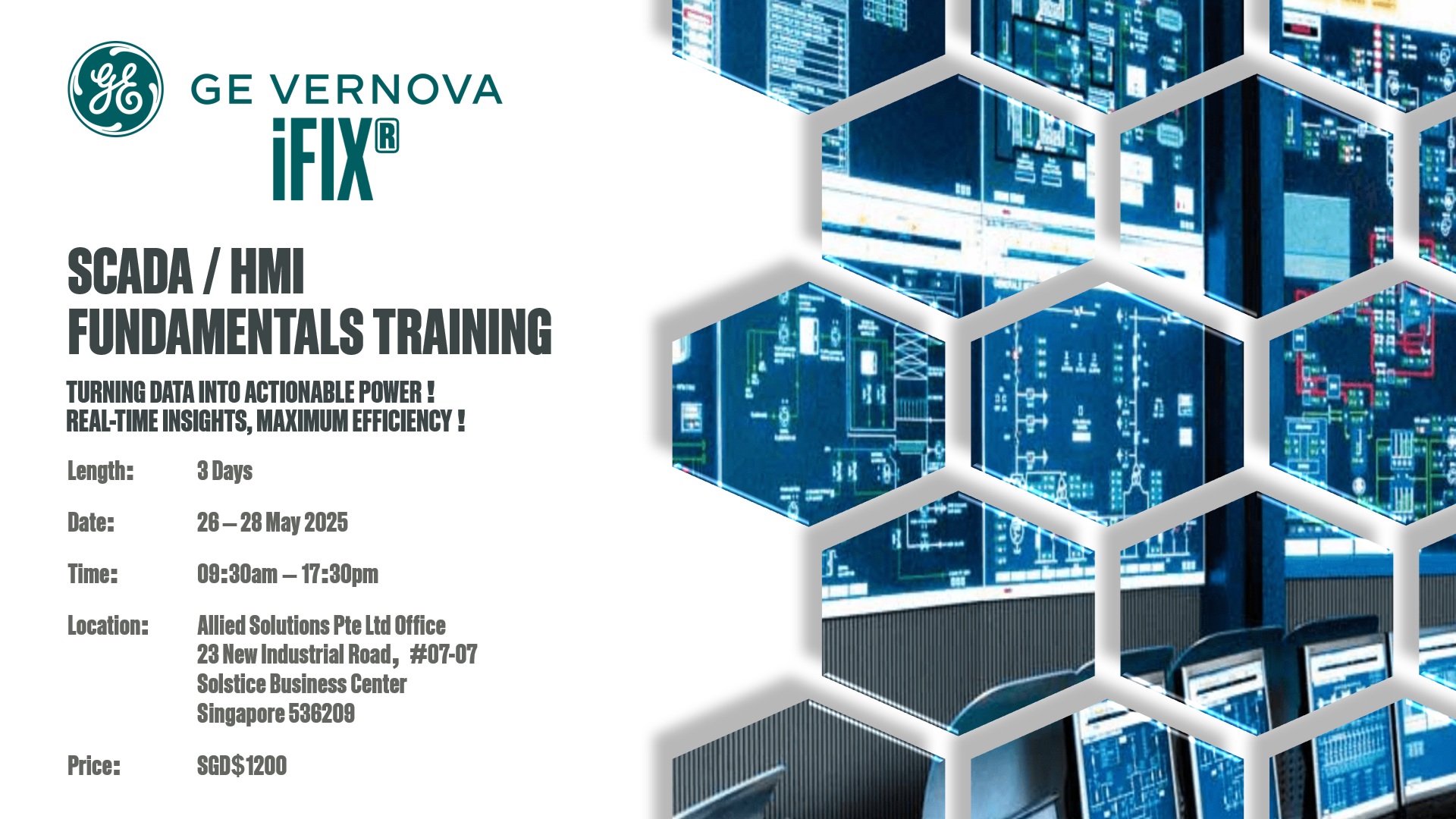

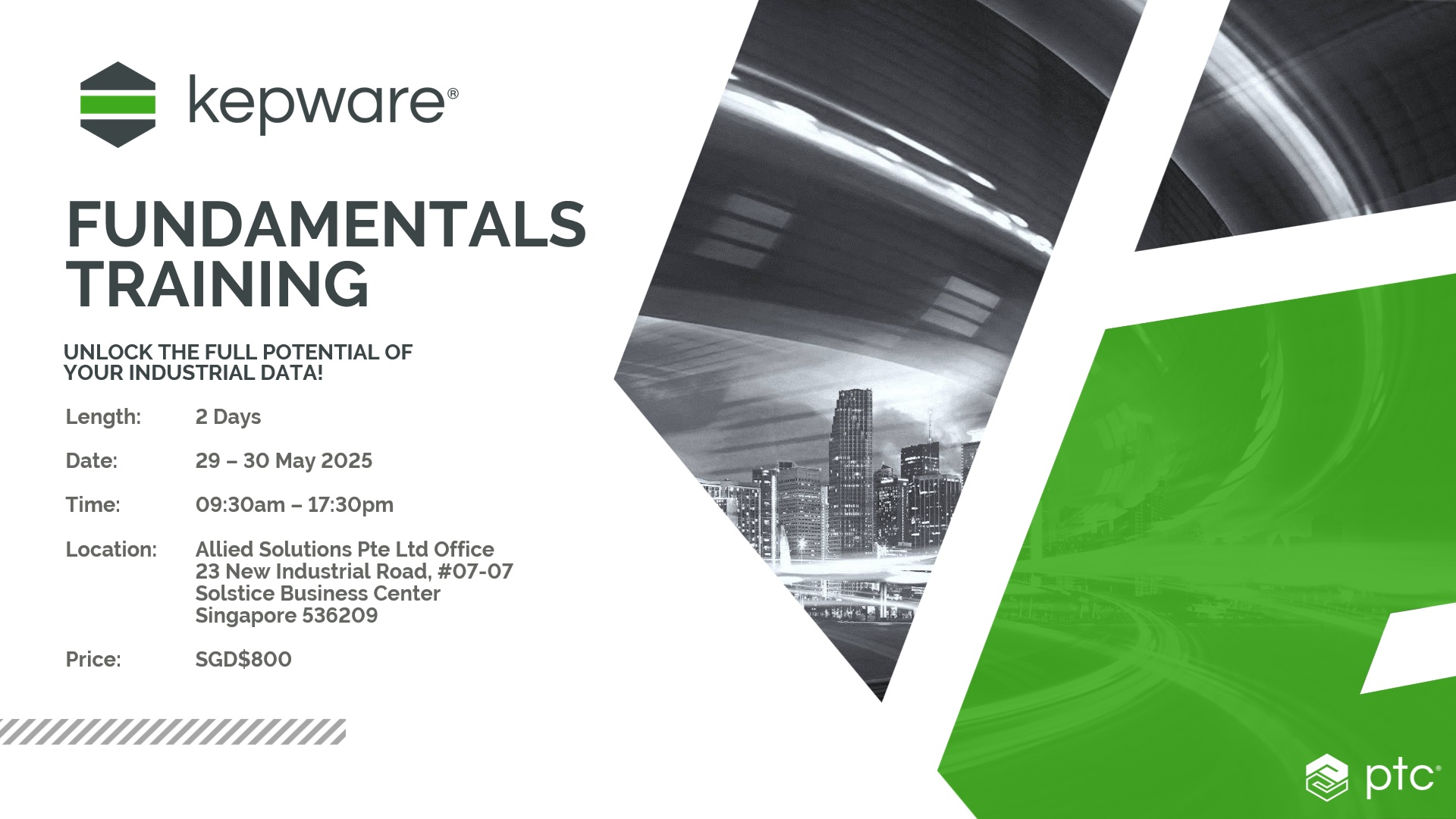

Training Week – May 2025

Select one or both of the upcoming training sessions to participate in.

Join Our 5-Day Training Programme

Enhance your skills in industrial automation by participating in our specialised GE iFIX and/or Kepware Fundamentals training sessions—an excellent opportunity to deepen your expertise and stay ahead in the industry.

Allied Solutions Ignites Innovation at EMAX & PMAX 2025

Experience the Future of Electronics & Manufacturing

💈 Booth No: A43 & A53

📅 Event Date: 23 – 25 July, 2025

📍 Venue: Setia Spice Convention Centre, Penang – Malaysia

Join Allied Solutions at EMAX & PMAX 2025! Explore cutting-edge automation software, OT connectivity, and MES solutions that drive efficiency and innovation in electronics and manufacturing. Experience live demos, engage with industry experts, and discover the future of smart manufacturing.

Unleash New Potential: What’s Inside GE iFIX’s Free Add-On?